Container Handling Freedom

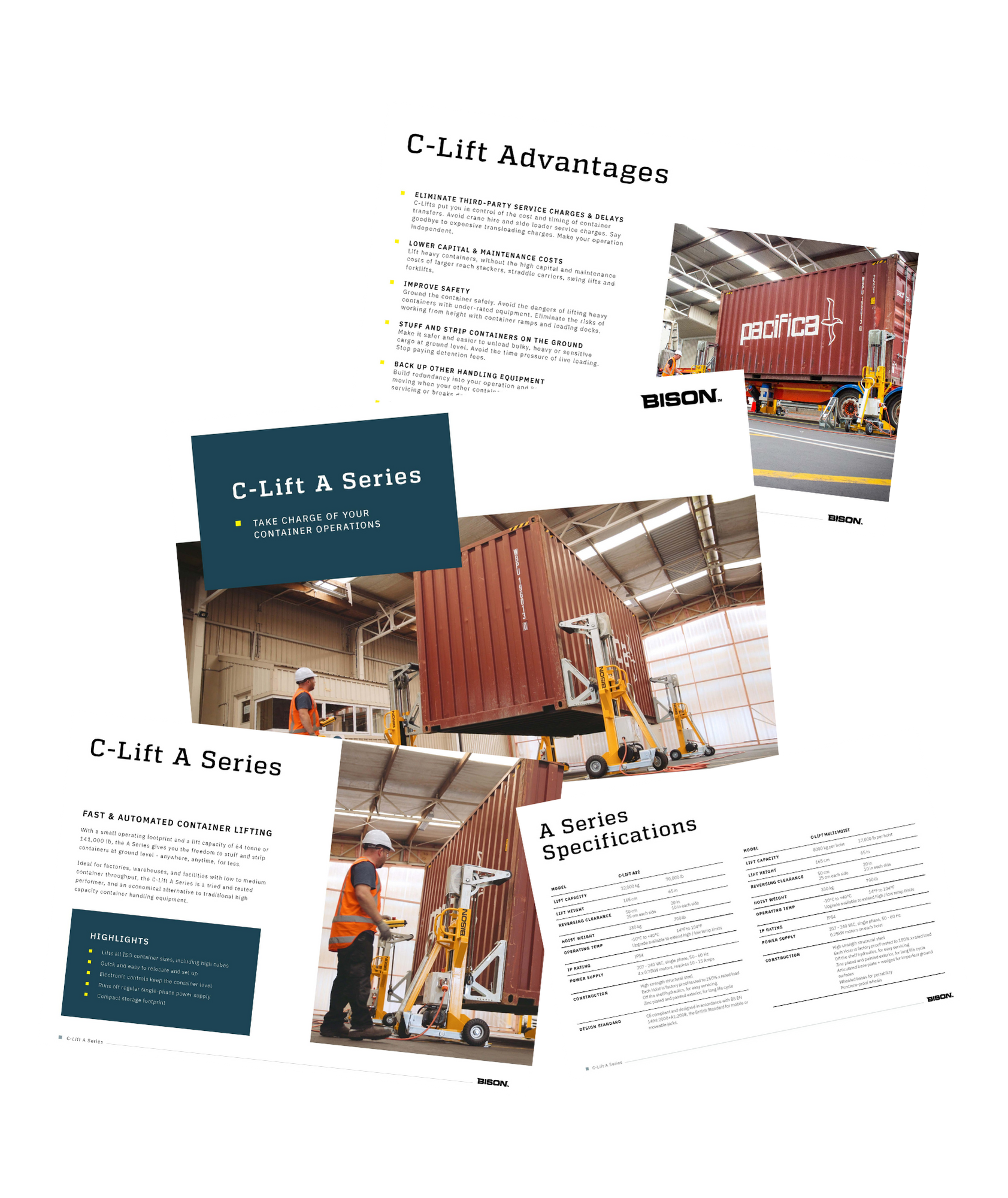

Compact and portable, the C-Lift A Series is a tried and tested performer, that is easy to relocate, set up and operate. The A Series will equip you to offload containers anywhere on site - including indoors and in tight spaces.

Ideal for factories, warehouses, and facilities with low to medium container throughput, the C-Lift A Series is a convenient and cost effective alternative to third party cranes, and requires a fraction of the capital investment and running costs of traditional container handling equipment. The A Series can be adapted to lift more than just shipping containers. Talk with our team about multi-hoist options.

Putting You In Control

Eliminate Crane Hire

Keep Operations Moving

Work At Sites Without Docks

Handle Cargo at Ground Level

No More Chassis Detention

Explore The Features

Request an Info Pack

New Multi-Hoist Option

Originally designed as a four-hoist system for lifting shipping containers, the A Series now features six and eight-hoist configurations, making it capable of handling heavier payloads of up to 64 tonnes.

It’s ideal for larger, longer, or more flexible loads that require support at multiple points along their length, with all lifting points operating in perfect unison to prevent flexing and potential damage to delicate materials like drywall or glazing in modular buildings.

Additionally, the system provides real-time load monitoring at each lifting point, ensuring precision and safety throughout the lift.

Manufacturer of Agricultural Machinery Eliminates Crane Hire Costs & Delays

“We are no longer dependent on outside companies and look forward to seeing reduced costs because of that."

- Bob Montville, Manufacturing Engineering Manager, Morris Equipment

C-Lift A Series

-

Wireless remote

A wireless handheld remote control allows the operator to move freely, monitor each lift, and remain a safe distance from the elevated container.

-

Hydraulic counterbalance valves

Hydraulic counterbalance valves ensure the container will stay elevated in the event of an unexpected power outage or hydraulic failure.

-

Emergency stops

An emergency stop button on the remote will stop the A Series on demand. A second hardwired emergency stop button sits on the ground, a safe distance from the elevated container.

-

Safety rated control system

A safety-rated control system, with dual-channel redundancy, controls the pumps and motors, keeping the container level and each leg synchronized.

-

Dual Lifting Cables

Dual lifting cables, rated to 5 times the working load limit, share the load on each leg. If one cable failed unexpectedly, the other cable can carry the full load by itself.

| Model | C-Lift A32 | C-Lift Multi Hoist | C-Lift A32 | C-Lift Multi Hoist |

| Lift Capacity | 70,000 lbs | 17,000 lbs per hoist multiplied by the number of hoists | 32,000 kg | 8000 kg per hoist multiplied by the number of hoists |

| Lift Height | 65 in | 1.65 m | ||

| Reversing Clearance | 20 in | 50 cm | ||

| Leg Weight | 727 lbs | 330 kg | ||

| Operating Temperature | 14°F to 104°F. Upgrade available to extend high/low temp limits | -10°C to +40°C. Upgrade available to extend high/low temp limits | ||

| IP Rating | IP54 | IP54 | ||

| Power Supply | 207 - 240 VAC, single phase, 50 - 60 Hz. 4 x 0.75kW motors, requires 10 - 15 Amps | 207 - 240 VAC, single phase, 50 - 60 Hz. 4 x 0.75kW motors, requires 10 - 15 Amps | ||

| Construction | High strength structural steel. Each leg is factory proof tested to 150% x rated load. Off the shelf hydraulics, for easy servicing. Zinc-plated and painted exterior, for long life cycle. | High strength structural steel. Each leg is factory proof tested to 150% x rated load. Off the shelf hydraulics, for easy servicing. Zinc-plated and painted exterior, for long life cycle. | ||

| Design Standard | CE compliant and designed in accordance with BS EN 1494:2000+A1:2008, the British Standard for mobile or moveable jacks. | CE compliant and designed in accordance with BS EN 1494:2000+A1:2008, the British Standard for mobile or moveable jacks. | ||

We Deliver More Than Just World-Class Products

Dedicated Support

Bison engineers stand ready to support your team and technicians. This support is enhanced by remote diagnostic capabilities built into all automated C-Lift A Series. Using a smartphone app, your team can connect Bison engineers to your C-Lift A Series, allowing us to investigate issues if they arise, reset the firmware, and provide expert advice at low or no cost, no matter where you are in the world.

Comprehensive Training

With every C-Lift A Series you'll receive a series of detailed Training Videos - covering safety, key components, how to set the A Series up, safe operation, and reversing safety. Each video is accompanied by a short online test, so that you can train, test, and certify your A Series operators, and take confidence knowing they are familiar with the equipment and how to use it safely.

5 Year Limited Warranty

All Bison C-Lift A Series are covered by a 5-year limited warranty on structural components, and a 1-year limited warranty on other components. Our product development and production processes combine first-class engineering, industrial-strength components, and rigorous manufacturing, to deliver quality equipment you can trust to perform in the toughest conditions.